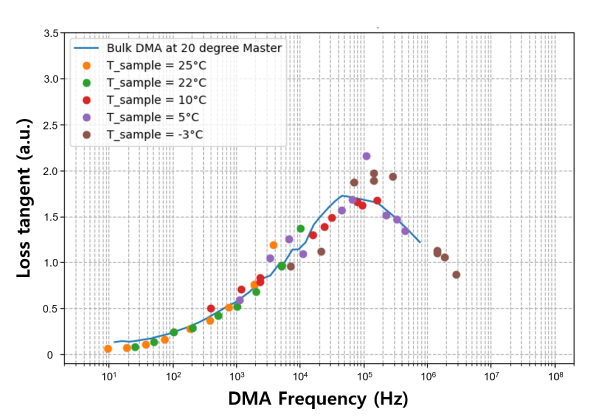

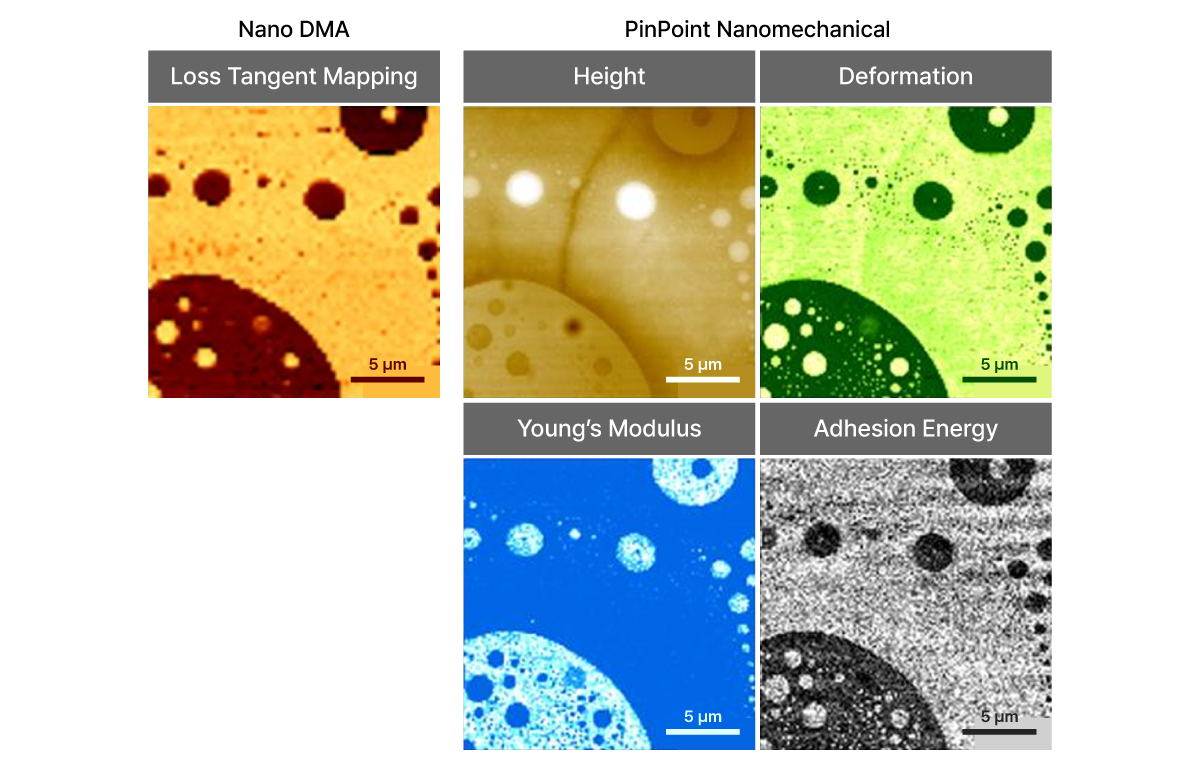

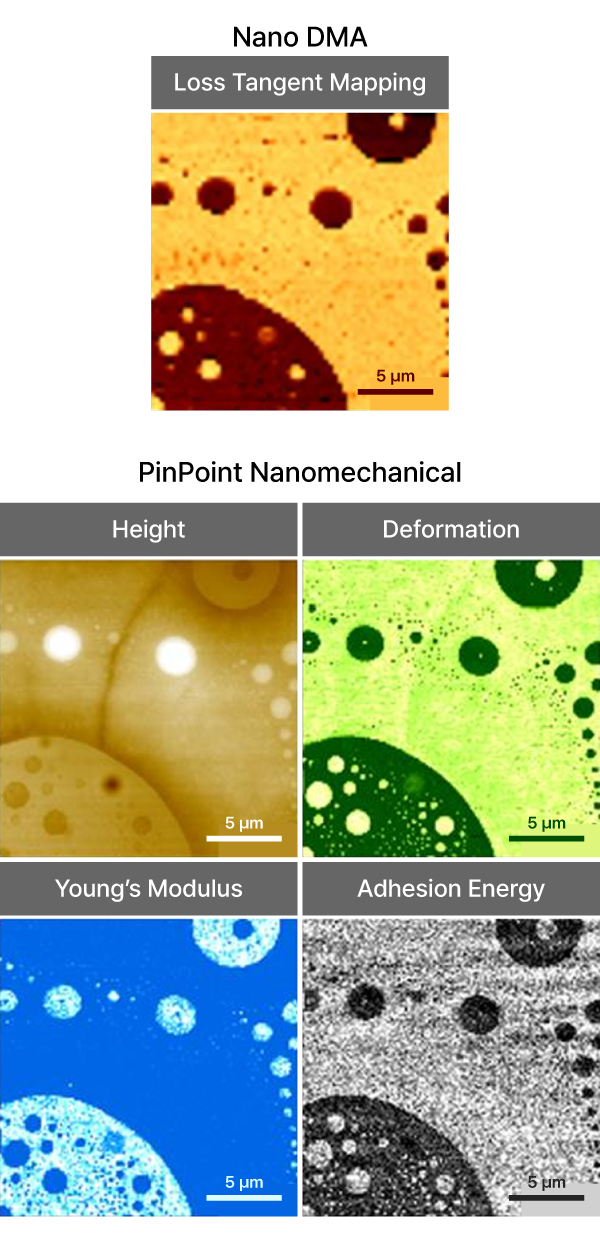

Dynamic Mechanical Analysis Spectroscopy

DMA Spectroscopy

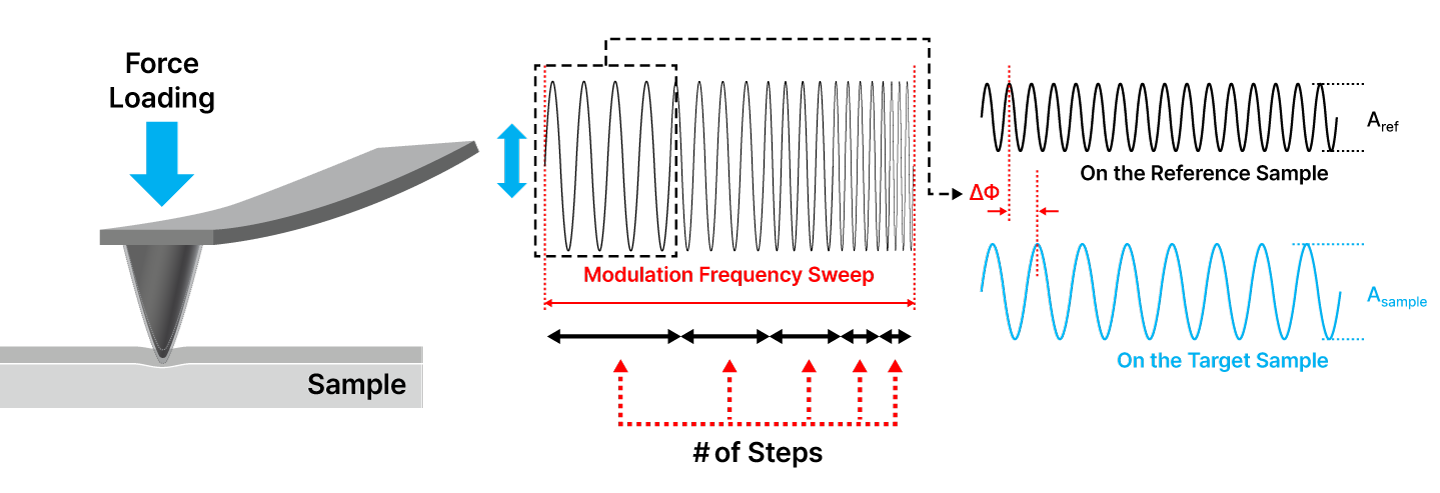

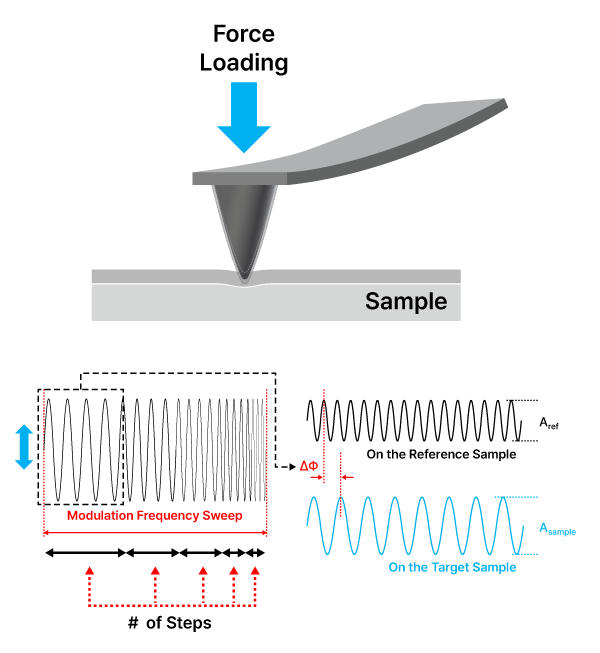

Nanoscale viscoelastic property measurement by applying oscillatory forces via the AFM cantilever and analyzing the frequency-dependent mechanical response